Where innovation sticks – Your perfect workplace starts here

From idea to implementation – we design your adhesive workplace that impresses today and excites tomorrow.

Whether in production, assembly, or craftsmanship – an optimally set up adhesive workstation is the key to precise, safe, and efficient processes. We support you from the analysis of your requirements to full implementation – including modern digitalization solutions, compliance consulting, and practical training. This is how we create workplaces that not only impress today but are also equipped for the demands of tomorrow.

Your advantages at a glance

- Efficiency increase – Optimized workflows and reduced setup times

- Quality assurance – Compliance with relevant standards (e.g., DVS 3320-2, ISO 21368)

- Digitalization – Integration of smart tools for process monitoring

- Ergonomics & Safety – Healthy work environment for your employes •Individual solutions – Tailored to your requirements

- One partner – all products and solutions from a single source

Our services

- Needs analysis & consulting: We review existing processes, equipment, and standard requirements.

- Planning & Conceptualization: Design of an optimal workplace layout including digitalization options.

- Implementation & Installation: Selection and integration of the appropriate technology and software.

- Training & Handover: Practical instruction of your employes for smooth operations.

- Service & Optimization: Long-term support and continuous improvement.

Success story: Smarter manual adhesive workstation of the future

Research project in collaboration with Fraunhofer IPA

As part of a research project by Innotech Marketing und Konfektion Rot GmbH in collaboration with Fraunhofer IPA, innovative approaches from workplace design were combined with approaches from digital process monitoring and control. In this context, the development of the "Smart Manual Adhesive Workplace" provided a technology demonstrator that offers insights into current automation and digitalization potentials in manual production. The focus was specifically on the field of adhesive technology.

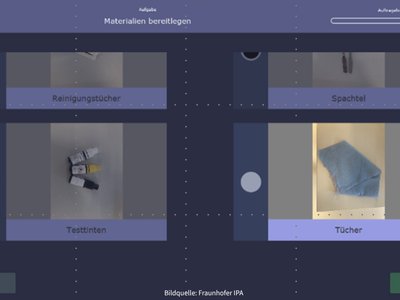

The respective user can scan their employe ID at the smart adhesive workstation and log in with it. Depending on the authorization, there is the possibility to create new work orders. No programming skills are necessary for this, as it can be created directly thru an admin tool with an intuitively understandable user interface. The employe is guided thru the process with checklists, illustrated work steps, or short videos, depending on the complexity of the task and their training level. He must confirm safety instructions, scan product information, and adhere to timers for pot life, ventilation, curing times, etc. The program displays these times to him live and only allows the subsequent work steps afterward.

Thru the consistent adherence to DIN EN ISO 21368, a high-quality and secure manufacturing process is ensured. The orders are structured in such a way that all necessary information is continuously captured and automatically documented during the work steps, including, for example, the relevant environmental conditions, which are autonomously captured and processed by the table. This enables seamless documentation of adhesive bonds in classes S1 and S2.

Download the full article directly here.