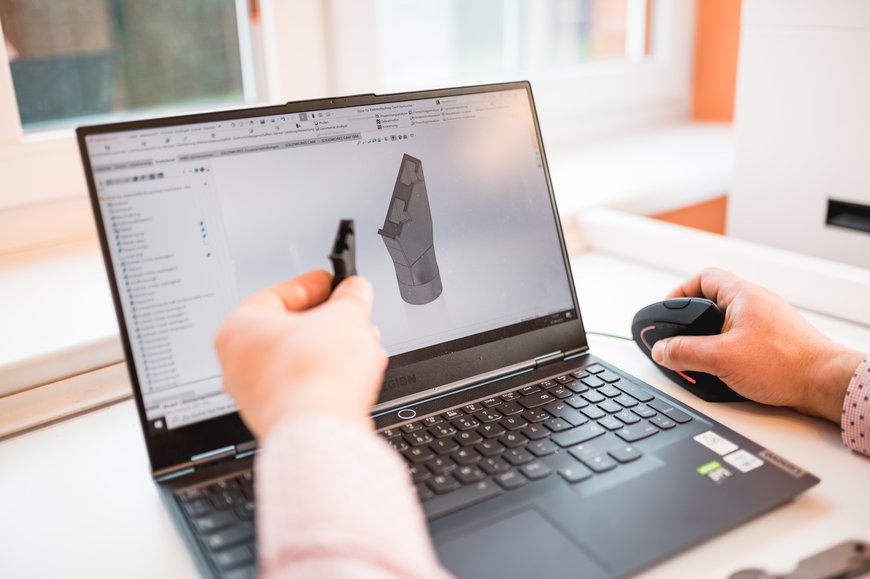

Customized special nozzles and static mixers using 3D printing technology

The last but decisive centimeter of adhesive!

The challenge for every customer is that the standard nozzle is not the optimum application method for almost any adhesive application.

With our customized cartridge tips and static mixers, we offer solutions that are specifically tailored to your needs. Our goal is to help you optimize your industrial bonding processes with repeatable accuracy.