Anyone who works with adhesive and fastening systems in an industrial environment has high expectations of the solution they use: it must function reliably, be flexible in application and perform well in a wide variety of situations. However, another factor is just as important: the expertise of the people who select and recommend these systems and support them in projects. Technical know-how and up-to-date knowledge are therefore essential.

In order to continuously expand this expertise, we conducted comprehensive training on the Weld Mount fastening system for our business developers and our sales and service staff last week. The aim was not only to understand the system in theory, but also to experience it in practice, thereby further strengthening our consulting and application expertise for our customers.

One system, many possibilities

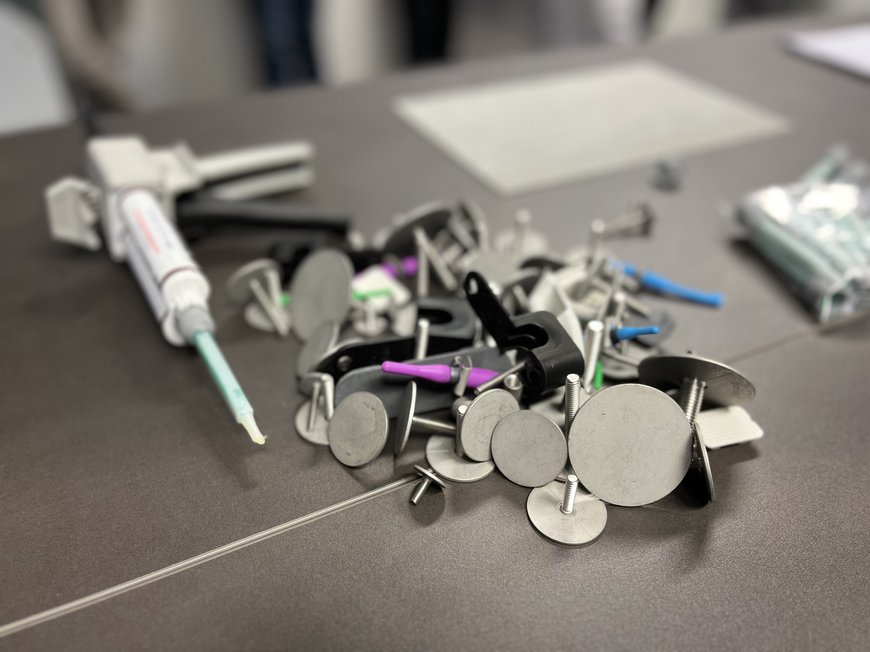

The Weld Mount System consists of more than 49 different components that have been developed for a wide range of applications. During the training course, all relevant components were presented in detail, their areas of application explained and their special features highlighted. This gave our employees not only a complete overview of the product range, but also a deep understanding of the respective technical strengths.

A central part of the training consisted of practical adhesive bonding tests. Here, the team had the opportunity to try out fastening solutions under real conditions, test different materials and simulate typical application scenarios. This practical experience is crucial for being able to make precise recommendations later on, because those who have experienced for themselves how the components can be processed and what performance they deliver are in a much better position to support customers.

Why the Weld Mount System is so impressive in use

During the training, our team not only learned about the individual components of the Weld Mount System, but also gained a deeper understanding of their practical benefits for typical application scenarios. The system's effectiveness is particularly evident when retrofitting cables and wires: fastening points can be created quickly, securely and without damaging the substrate. This is a decisive advantage wherever existing structures must not be compromised – especially in lightweight construction and steel construction. The practical adhesive tests carried out during the training course demonstrated how strong and reliable the connections are. This results in clear added value: more efficient installations, reduced costs and significant time savings while protecting surfaces.

Expert advice and technical support

With our newly expanded knowledge of the Weld Mount System, we can now offer you, our customer, even greater added value. Whether in project planning, technical support or business development, our teams are able to propose concrete solutions based on in-depth knowledge and to use the entire range of the system in a targeted manner.

For you as a customer, this means:

- More precise recommendations tailored to individual requirements

- Greater certainty when selecting suitable fastening components

- Support in the efficient implementation of technical projects

- A contact person who not only sells, but also understands

Competence as part of our commitment

Training is another step in our continuous development process. It underlines our commitment to not only supplying high-quality products, but also providing a team that knows these products in detail and can use them professionally. Because we are convinced that a good adhesive solution is always a combination of a strong system and people who know how to achieve optimal results with it.

We look forward to incorporating our expanded expertise into your projects and providing you with competent support for your current and future challenges.

Frequently Asked Questions (FAQ)

Question: What is the Weld Mount System and why is it used?

Answer: The Weld Mount System is a versatile fastening solution with numerous components designed for various industrial applications. It enables strong attachment points without damaging the substrate. This makes it especially useful in areas where surfaces must remain intact, such as lightweight construction and steel construction.

Question: What advantages does the Weld Mount System offer for cable and wiring installations?

Answer: The Weld Mount System allows attachment points to be created quickly, safely, and without harming the material. It simplifies the retrofitting of cables and wiring because no structural changes are required. This leads to more efficient installations, lower costs, and significant time savings.

Question: Why is internal Weld Mount training important for employees?

Answer: The training provides both theoretical knowledge and hands-on experience with the system. Employees can test components, simulate real application scenarios, and better assess the system’s performance. This significantly improves their ability to advise customers and support technical projects.

Question: How do customers benefit from the team’s enhanced application expertise?

Answer: Customers receive more precise recommendations tailored to their specific technical requirements. The team can propose suitable solutions, use the full range of products effectively, and support projects more efficiently. This increases confidence in selecting and using the appropriate fastening components.

Question: Which applications are particularly well suited for the Weld Mount System?

Answer: The system is ideal for situations requiring fastening without weakening the underlying structure. This includes lightweight construction, steel construction, and any application where surfaces must remain undamaged. Its high strength and reliability make it suitable for demanding industrial projects.